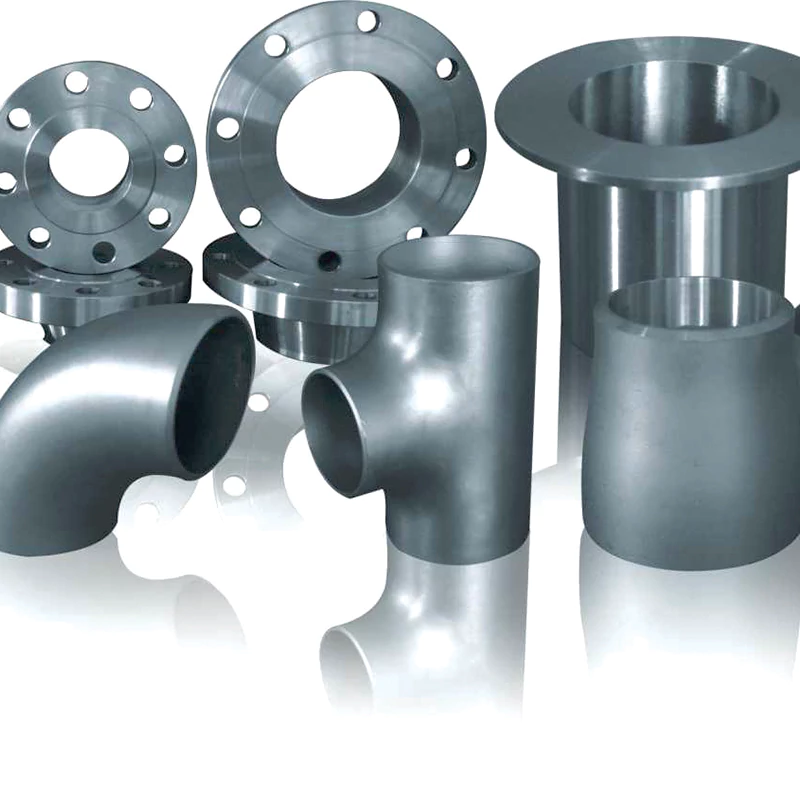

FITTINGS

welded joints

Welded fittings is a branch of fittings that has two categories: Welded Butt Weld Fittings and Manisman Welded Fittings. The main difference between welded joints and high pressure joints is in the way they are connected to the pipe. Of course, other things such as the way of construction and the type of construction materials also play an important role in creating differences in these two types of connections. Welded joints are connected to the pipe by butt weld, but the high pressure joints are either threaded and are connected by screws or are butt welded and the pipe inside them is placed on a step and from Welding is done outside.

Welded joints

Welded joints, as their name suggests, have a welded seam. During the construction of this type of joints, carbon steel, stainless steel or any type of molten steel alloy is poured into two molds and then connected by electric welding to complete the construction, or from a part Sealed pipe is used to make them. The presence of a welding seam in the head to the body of welded joints increases the possibility of their corrosion and damage by chemical fluids compared to Manisman welded joints, especially if this welding is not even and clean, this possibility is much higher. Fittings have several types according to what they have to do in piping systems, which will be explained in detail below.

90 degree seamed knee

A 90 degree bend allows the flow to be changed by 90 degrees. This piece has two types, LR (Long Radius) and SR (Short Radius), and as mentioned, it is made from a seamed pipe.

45 degree seamed knee

Like the 90-degree elbow, the 45-degree elbow also has the task of changing the flow path by 45 degrees. 45 elbow is one of the most widely used fittings in the industry and like 90 elbow, it has two types SR and LR.

Seamless tee

Equal Tee, also called Equal Tee, is used to create a branch in the pipe. When there is a need to create a branch equal to the main pipe in a pipe, a jointed equal tee is placed by welding as a connection between the three pipes.

Uneven seamed tee

Unequal tee like equal tee is used as an interface for branching from the pipe and is widely used in the water and sewage industry and water supply pipelines. Unequal Tee is also known as Unequal Tee and Reducer Tee. The branch that branches off from the unequal tee is smaller than the diameter of the main pipe, and the presence of the word unequal in the name of this piece is also the reason.

Seamless conversion

Another one of the most widely used connections in the industry is the reducer. When it is necessary to make the diameter of the pipe smaller or larger in a part of the pipeline, they use conversion. One side of the reducer has a larger diameter and is the same size as the larger pipe, and the other side has a smaller diameter and is the same size as the smaller pipe. Transformations have concentric and non-concentric types, which should be used depending on the situation.

flange

Types of flanges

Throat flange

Weld Neck Flange is a type of flange that has a conical neck and is connected to its center.

blind flange

A blind flange is like a disk that is used to block the passage of fluids at the end of the pipeline. Therefore, unlike other flanges, the blind flange does not have a section for the passage of fluids.

Welded silent flange

To connect the flange and the pipe, after placing the pipe inside the silent weld flanges, fillet welding is done from the outside.

ribbed flange (threaded)

Threaded flange, which is also known as gear flange, has threads inside and is connected to the pipe in the form of a screw.

Slipon flange

This flange is connected to the pipe by welding. In order to connect the pipe and slipon flange, first the pipe is placed inside the flange and then it is fillet welded from the inside and outside to have better sealing.

Flange ring joint

Flange Ring Joint (RTJ) is a type of flange that has a groove on its body. This groove or depression exists on the side of the face of the flange and makes this flange have a good sealing at high temperature and pressure.

Contact our sales experts to inquire about the price of all types of flanges.