All Kinds of Gaskets

Gaskets are produced and offered in various types and standards. Generally, they can be categorized based on their constituent materials into the following types:

- Non-metallic

- Metallic

- Composite

Non-metal

Non-metallic Gaskets can be easily compressed under low pressure.

They are typically used in low-temperature applications, although the graphite type can endure temperatures up to 500 degrees Celsius.

Non-metallic Gaskets are the most affordable and widely available type of gaskets.

The most common materials used in this type of gaskets include the following:

graphite

rubber

Teflon

PTFE

Compressed non-asbestos fiber (CNAF)

These washers are also known as soft washers.

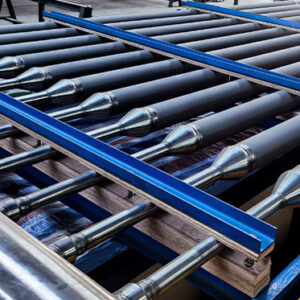

RTJ or metallic

These gaskets are also known as ring gaskets or RTJs.

Metal gaskets are used in high pressure, they can also be used in high temperatures.

When using metal gaskets, high pressure is required to ensure a proper fit between the surfaces for effective operation.

Various materials are used to make metal gaskets, which include the following:

soft iron

Low carbon steel

Stainless steel

Monel

Inconel

RTJ gaskets are highly durable but also costly.

Composite or semi-metallic

Composite gaskets are made from a blend of metallic and non-metallic materials, with different material combinations used depending on the specific application.

Composite gaskets can be used at different pressures and temperatures.

While composite gaskets are generally more cost-effective than metal gaskets, they require more precise installation.

Spiral wound and corrugated gaskets are well-known in composite categories.