Today, with the rapid industrial advancements in installations and piping, understanding the distinction between steel pipes and tubes is essential. Both are critical components across various industries and facilities, and there is a wide range of steel pipes and tubes available on the market, each in high demand. Recognizing the difference between steel pipes and tubes is crucial for their effective application in different industries. The most noticeable distinction between these two products lies in their appearance.

First, we will introduce the pipe, followed by the tube. In the subsequent sections, we will explore the characteristics of steel pipes and tubes. Finally, we will highlight the key differences between them.

A pipe is a hollow cylindrical structure with a circular cross-section, defined by its specific outer diameter, wall thickness, and length. It is primarily used for transporting fluids. The characteristics and specifications of tubes differ from those of pipes, which we will detail in this article.

To understand the difference between steel pipes and tubes, it’s important to note that both “pipe” and “tube” refer to a tubular form. However, “pipe” is generally used for transferring fluids over long distances, while “tube” is primarily used for fluid circulation within confined systems or machinery, for power transmission, and in instrumentation systems.

Steel pipe and its specifications

As previously mentioned, a tube is a hollow container with a circular cross-section used to transport fluids. Tubes can be made from various materials, including steel, fiberglass, and concrete. Steel pipes, which are widely used across industries, are classified into two main categories: seamed and seamless (Manisman).

Welded steel pipe

These pipes are created by welding the edges of rectangular sheets and then bending and shaping them. The two edges are connected using methods such as electrical resistance welding (ERW) and electrical fusion welding (EFW). Typically, welded steel pipes are produced from steel sheets.

Also, seamed pipes are divided into two categories according to the type of seam:

• Straight Seam Pipe

• Spiral Seam Pipe

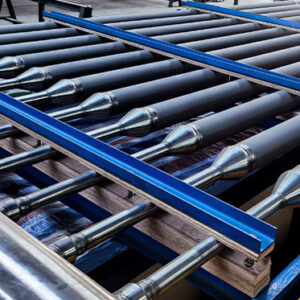

Seamless steel pipe

These pipes are manufactured using solid and circular cross-section ingots, which are shaped through the application of heat and tension by rollers. Seamless pipes are typically produced with a diameter of up to 16 inches.

Tube and its specifications

Tubes come in circular, square, and rectangular sections and are used for heat transfer, high pressures, and temperatures. They are commonly employed in applications such as oil furnaces and heat exchangers and are typically manufactured up to 12 inches in diameter, with a seamless design. Pipes, however, are available in two types: seamed and seamless, which is one of the many distinctions between steel pipes and tubes.

The thickness of tubes is a key characteristic. Unlike pipes, where the thickness can vary, the thickness of tubes remains consistent throughout. The nominal diameter and the outer diameter are always equal, and the outer diameter is fixed, similar to pipes. The thickness class is defined by BWG.

The difference between steel pipe and tube

The distinction between steel pipes and tubes is an important consideration in engineering. Generally, pipes have circular cross-sections, whereas tubes can have circular, square, and rectangular cross-sections. However, it’s important to note that the dissimilarity between steel pipes and tubes goes beyond just their appearance. Here are a few key points to consider:

• The size of tubes is indicated by their outer diameter (OD) only, while pipe sizes vary: for pipes with a diameter smaller than 12 inches, the size is indicated by the inner diameter; for pipes larger than 12 inches, the size is shown by the outer diameter.

• Tubes are generally used to transport fluids and in closed systems such as heat exchangers. They are also sometimes used as substitutes for beams, cans, and corners in building construction.

• The cross-sectional area of tubes can be circular, square, or rectangular, whereas pipes always have a circular cross-section.

• Tubes do not have a specific length, while pipes are manufactured to specific lengths.

• The thickness of tubes has dimensional tolerance and can vary along their length, while the thickness of pipes is uniform throughout.

• Pipes typically have standard dimensions, whereas tubes can be produced in custom dimensions according to the customer’s order.